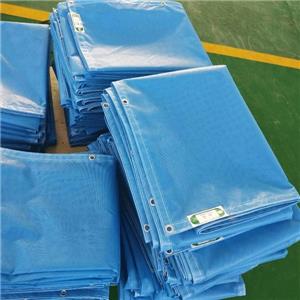

Lumber Shield Cover Wood Lumber Packaging Wrap

- Bollison

- China

- 25days

- 200000pcs/Month

Weather and sunlight resistant, our lumber wraps are ideal for long term storage. Available in various weave strengths, colors, laminations, coatings and with paper backing.

The Lumber Wraps available in the market is a high-density polyethylene scrim with a low-density polyethylene coating. All these lumber wraps have UV protection, and you can select them in several different colour specifications.

Tear-resistant, strong and durable is lumber wraps preserving your timber from harsh environmental conditions.

Lumber Shield Cover Wood Lumber Packaging Wrap

Lumber Wraps have most definitely become an essential product in the timber industry. Whether it is for transition, long-term storage or packaging lumber, joists, and other wood products, lumber wraps are a cost-effective product of modern technology. Made of reinforced polyethylene scrim laminated to Kraft paper on the back and coating the upper side with polyethylene, lumber wraps help you to protect your wood as the same day it was cut.

What kind of Lumber wraps are available?

Woven lumber wrap can be manufactured in a wide range of thicknesses in the form of sheet rolls or structure covers,and it included plain Lumber Wrap and Printed Lumber Wrap.

The standard woven lumber wraps are made to roll widths of 60”, 72”, 96”, 108” and 144.” And also, they can be made to 1000 feet and 2000 feet lengths. When a requirement arises to have a lumber wrap made in customized sizes, such needs can be fulfilled by manufacturing them to suit the customers’ needs.

Why do you need to choose lumber wrap instead of poly sheeting?

The first fact is that special features that the lumber wrap consists makes it a cost-effective product to buy.

The second reason is to solidify the structure of the high-density polyethylene weave. Other similar products are considerably brittle than woven lumber wrap, and lumber wrap provides flexible and lasting coverage for the timber.

Why do you need to choose two-colour Lumber Wrap?

Woven Lumber Wraps can be manufactured in any colour dyes of polyethylene, so there is a wide range of selection for anyone to choose the colour that suits them. The standard colour for woven lumber wrap one side being coated with white poly and the remaining side with black poly. This colour combination allows the woven wrap to be resistance towards the impact of sunlight by making it a reflective surface. The black coated side provides shade to the timber, maintaining a cooler temperature when the white-coated surface becomes the reflective exterior. So basically, the opacity both the layers generate helps the lumber wrap to reduce building up of heat and condensation. As a result of this, the specifications in white/black woven lumber wrap, it prevents the mold growth because of the maintained lower temperatures. Also, the lumber wrap covers timber from sunlight, so this does not get any UV sun damage. The sunlight can easily bleach out the colour of wood, but the white/black specification in woven lumber wrap allows a solid packaging for wooden products. And its minimal elongation helps to retain the shape of the product.