HDPE 3D Composite Geonet Strong Drainage Composite Net

- Bollison

- China

- 25days

- 1000000m2 per month

The 3D Composite Geonet is for Landfill drainage,roadbed and road drainage,railway drainage, tunnel drainage, underground structure drainage,the retaining back wall drainage, gardens and sports grounds drainage.

Drainage geocomposites geonet are manufactured using a unique geotextile filter developed specifically for use in drainage geocomposites for its high tensile modulus and ability to prevent soil ingress into the void space of the drainage core.

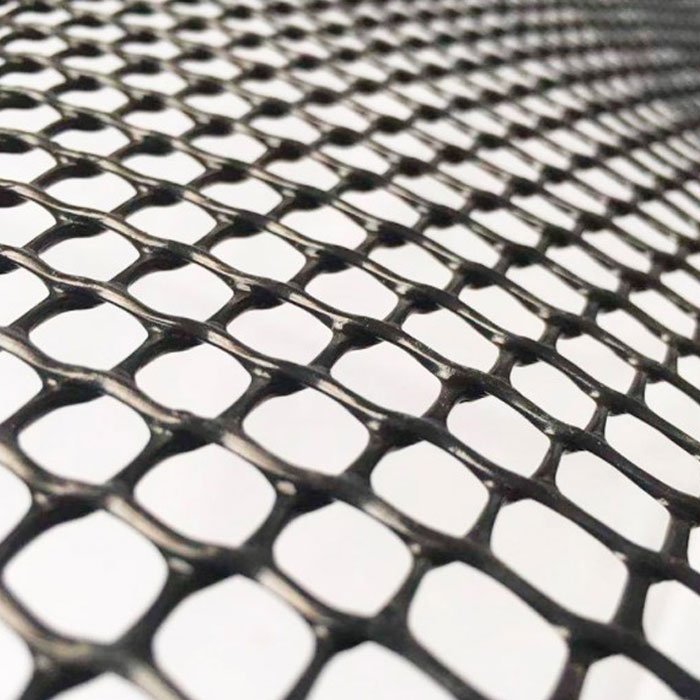

The drainage cores are manufactured from HDPE nets which have been engineered to have good flow under high loading.

HDPE 3D Composite Geonet Strong Drainage Composite Net

Drainage Composite Geonet Description

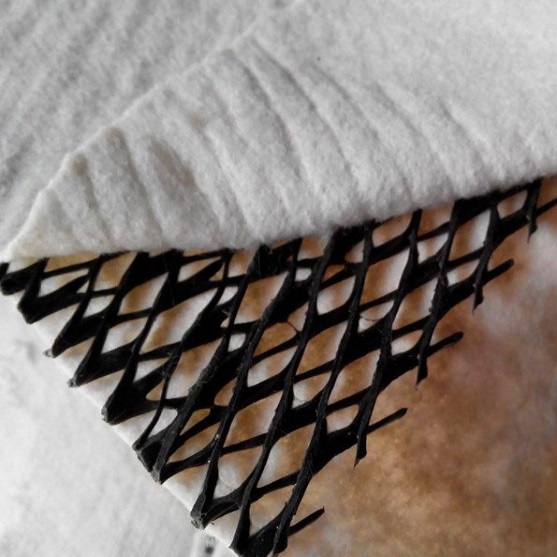

3D Composite Genet for drainage is a new type of geosynthetics.3D composite drainage geonet is made of special geonet with double -side bonded geotextile.The combination of geotextile (reverse filtration) and geonet(drainage and protection) provides a cpmplete "reverse filtration-drainage-protection" effect.The special 3D structure of the mesh can with-stand high compressive loads during the entire use process,and can maintain a considerable thickness,provide good permeability.It can replace traditional sand and gravel layers,and is mainly used for drainage of landfills,roadbeds and inner walls of tunnels.

Geonet NetWork Specifications

Drainage network core | units | Specification | |||

Unit weight | g/m2 | 750 | 1000 | 1300 | 1600 |

Thickness | Mm | 5.0 | 6.0 | 7.0 | 7.6 |

Hydraulic conductivity | m/s | kx10-4 | Kx10-4 | Kx10-4 | Kx10-4 |

Elongation | % | 50 | 50 | 50 | 50 |

Tensile strength (core netwaork) | kN/m | 8 | 10 | 12 | 14 |

Geotextile | g/m2 | 200-200. Heavier grades of geotextiles can be bonded to geonet on request | |||

What's the 3D Composite Geonet Typical Applications include?

− Highways: vertical edge-of-carriageway drains intercept the lateral flow of ground water. Modern fin drains reduce excavation, reduce backfill quantities and reduce installation time. In-slope drainage increases geotechnical stability.

− Retaining walls and bridge abutments: to reduce pore water pressure and avoid backfill saturation.

− Engineered landfills: with the additional requirement of long-term chemical resistance and high compressive strength.

− Tunnels: ground-water-seepage interception between rock face and the tunnel lining.

− Buried structures: vertical and horizontal drains for basements, culverts, car parks, reservoirs, etc.

3D Drainage Geonet Feature

1. Drainage strong (equivalent to one meter thick gravel drainage).

2. High tensile strength.

3. To reduce the probability of geotextile embedded core, to maintain long-term stability of the drainage.

4. Long-term high-pressure load (can withstand about 3000Ka compression load).

5. Corrosion-resistant, acid and alkali, long service life.

6. Construction convenience, shorten the construction period, reduce costs.

What's the advantages of 3D Composite Drainage Geonet ?

Fast drainage-----The middle strip is rigid, forming a linear drainage channel in the drainage direction, and the ribs on both sides are arranged in a cross to increase the overall stability of the drainage network.

Good flexibility and permeability In coastal engineering, use its characteristics of good flexibility and permeability to buffer

the impact energy of waves.

Strong high pressure load----Can withstand a compression load of about 3000A for a long time.

Good performance----Made with three-layer special structure, flexible and durable, strong acid and alkali resistance, not perishable, and long service life.

Reduce cold expansion----Laying a three-dimensional composite drainage net can help reduce the impact of frost

heave.

Uniform mixing------It can hydrate the concrete evenly, whether it is for rigid roads or flexible road systems.